ENGIE and POSCO Holdings entered into an agreement to undertake a pre-feasibility study for a prominent green hydrogen initiative in Western Australia’s Pilbara region.

This agreement aims to provide green hydrogen to the proposed Hot Briquetted Iron (HBI) facility operated by POSCO Group in Port Hedland, facilitating the production of environmentally friendly iron.

Additionally, there is potential for the project to supply green fuel to South Korea as part of POSCO’s commitment to decarbonizing its existing assets.

The Green Hydrogen Pre-feasibility Study Agreement between Engie and Posco - About

The study aims to enhance the development plans for renewable energy sites in the Pilbara, encompassing wind and solar generation, a hydrogen electrolyser, large-scale storage capacity, and a pipeline for transporting green hydrogen to POSCO Group’s HBI plant (POSCO Port Hedland Green Steel – PGHS) once it’s operational.

Hot Briquetted Iron (HBI) is a high-purity iron product produced by compacting direct-reduced iron at high temperatures, with an iron content of typically over 90%. It is used in steel production due to its purity, convenient size, and eco-friendly attributes. HBI offers several advantages:

- High Iron Content: HBI contains over 90% iron, making it a concentrated iron source.

- Low Impurities: It has minimal impurities like sulphur and phosphorus, ensuring high purity.

- Compact Size: HBI has a consistent and manageable shape, facilitating handling and transportation.

- Environmental Benefits: Its production is typically associated with lower carbon dioxide emissions compared to traditional iron production methods.

The POSCO Port Hedland Green Steel (PHGS) project will produce low-carbon iron and steel by reducing iron ore through Direct Reduced Iron (DRI) technology and Hot Briquetted Iron (HBI) production, using green hydrogen as a reducing agent in the process.

POSCO Port Hedland Green Steel (PHGS) - About the Project

According to information available from the Environmental Protection Authority of Western Australia, Port Hedland Green Steel Pty Ltd (owned by POSCO) is planning to develop the Port Hedland Green Steel Project – Stage 1 in the Boodarie Strategic Industrial Area (BSIA), approximately 10 km southwest of Port Hedland in the Pilbara region.

This project will comprise a pellet plant and a hot briquette iron (HBI) plant, consuming around 3 to 3.5 million tonnes of iron ore per annum (Mtpa).

Most of the pellets will be directed to the HBI plant to generate roughly 2 Mtpa of HBI. In contrast, the remaining pellets, approximately 0.7 Mtpa, will be exported from the Port of Port Hedland as pellets.

The proposed facilities will encompass:

- An iron ore processing facility (IOPF) featuring one pellet and one HBI plant producing about 2 Mtpa of HBI and 0.7 Mtpa of iron ore pellets.

- Hydrogen production and storage facilities to supply the IOPF.

- A nitrogen plant.

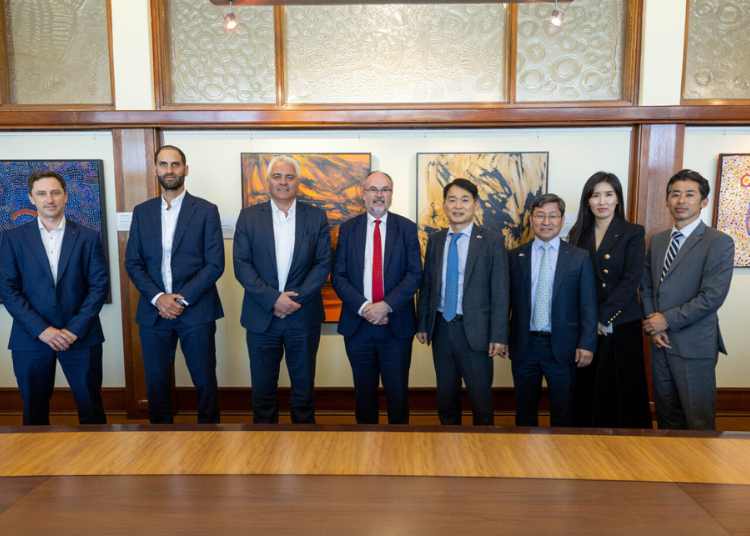

The Green Hydrogen Pre-feasibility Study Agreement between Engie and Posco - Leadership Comments

ENGIE Australia & New Zealand's CEO - Comments

ENGIE Australia & New Zealand’s CEO, Mr. Rik De Buyserie, emphasized the significance of the pre-feasibility study, marking ENGIE’s initial steps in expanding its hydrogen initiatives in Australia and entering the energy market’s burgeoning hydrogen sector.

He stated that ENGIE is dedicated to expediting the transition towards a carbon-neutral economy. Developing green hydrogen for use in reducing emissions from heavy manufacturing plays a vital role in assisting partners in realizing their sustainability objectives.

Furthermore, Mr. De Buyserie highlighted the enthusiasm and potential benefits of decarbonization, pointing out that this endeavour could result in the creation of new jobs within emerging industries.

Head of POSCO Holdings' Hydrogen business unit - Comments

Mr. Ju-ik Cho, Head of POSCO Holdings’ Hydrogen business team, emphasized the strategic importance of Australia in POSCO Group’s pursuit of carbon neutrality and the development of green hydrogen businesses for a sustainable future. He noted that Australia is a key country for advancing these objectives.

Mr. Cho further outlined POSCO Holdings’ aims, which encompass creating a successful green hydrogen development model that can be seamlessly integrated into green steel production in Australia.

This initiative is not only focused on sustainable operations but also on establishing a robust business structure that fosters local synergy within the POSCO Group.

This endeavor underlines the group’s commitment to green technologies and sustainable practices, which aims to achieve carbon neutrality by 2050 by the adoption of hydrogen reduction processes in iron and steel making.