Worley has secured a contract from Iluka to deliver engineering, procurement, and construction management (EPCM) services for the Balranald Critical Minerals project in New South Wales, Australia.

Situated in the Riverina district of southwestern New South Wales, the project primarily centres on the West-Balranald deposit, which is abundant in rutile and zircon and houses significant quantities of rare earth minerals.

Balranald Critical Minerals Project - About it

The primary objective of Balranald’s project is to extract and process minerals to manufacture high-grade, top-quality critical mineral products within Australia.

Critical minerals, essential for various sectors such as technology, defence, energy, and manufacturing, hold immense economic importance and are identified as critical due to the potential risks associated with disruptions or scarcity in their supply chain.

According to Iluka, upon completion, the new critical mineral plant will be able to produce on average per year:

- 60ktpa rutile; 50ktpa zircon;

- 50-70ktpa synthetic rutile;

- 4ktpa rare earth concentrate (REC); and

- 150ktpa sulphate ilmenite

The deposits are situated around 60 meters below the surface, and over several years, Iluka has evaluated the potential for developing this site using innovative underground mining (UGM) technology.

This method allows access to previously deemed uneconomical ore bodies while ensuring lower environmental impact and reduced carbon intensity compared to conventional extraction methods.

Balranald Critical Minerals Project - Investment Details

In February 2023, Iluka confirmed its final decision to invest in the project and released an overview of the company’s investment. The summary is outlined below:

Balranald Project | Details |

Location | Riverina, NSW, Australia |

Average annual production | 60ktpa rutile; 50ktpa zircon; 50-70ktpa synthetic rutile; 4ktpa rare earth concentrate (REC); and 150ktpa sulphate ilmenite |

Capital cost | $480 million (Class 3 – target accuracy of -15% / +30%) |

Construction period | 18 months, with first production expected in H1 2025 |

Initial anticipated mine life | 9.5 years |

Net present value | $400 million |

Expected Payback Period | 3.0 Years |

Technology evolution | Significant; sustainability benefits include a substantially reduced disturbance footprint and carbon intensity. |

Market for Balranald Critical Minerals

The minerals which will be extracted and processed in the new plant has multiple applications, such as:

- Rutile: Used mainly for making titanium dioxide, a key pigment in paints, plastics, and paper due to its brightness and opacity.

- Zircon: Primarily utilized in ceramics for its role as a glaze opacifier and in refractories for added strength and resistance to corrosion.

- Rare Earth Concentrate: Essential for electronics (such as smartphones and renewable energy technologies) and as catalysts in diverse chemical processes.

- Sulphate Ilmenite: Used for producing titanium pigments, crucial in paints, plastics, and paper, and in making titanium metal for aerospace and high-performance alloys.

Balranald Critical Minerals Project - Worley as the EPCM Contractor

Iluka has contracted Worley, a global professional services company specializing in energy, chemicals, and resources, headquartered in Australia, with the primary EPCM (Engineering-Procurement-Construction-Management) Services Contract.

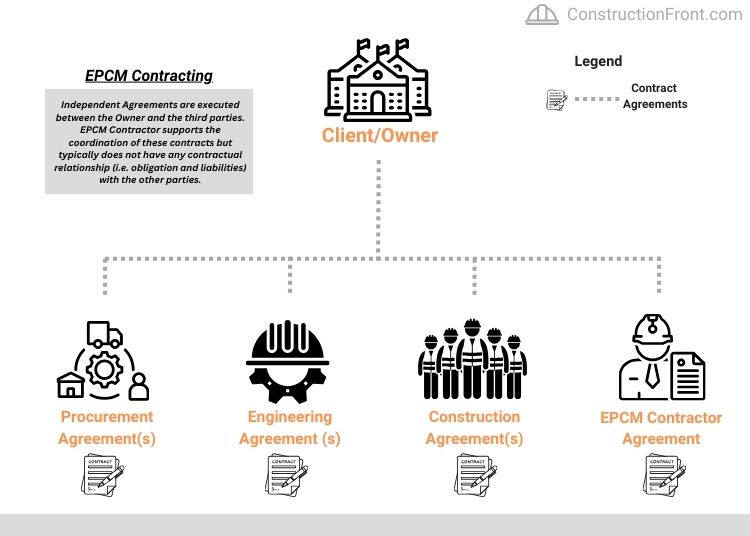

Typically, within the EPCM framework (further details below), the Contractor (e.g. Worley) collaborates closely with the Client (e.g. Iluka) to facilitate pivotal project decisions.

This includes refining technical requirements, scope of works and procurement management, offering guidance on design development and value engineering, and overseeing overall construction management during the delivery phase.

Suggested Reading: What are EPC and EPCM Contracts? (Key Features, Examples, and Tips)

In its market announcement, Worley highlighted its intention to leverage its Australian team in collaboration with specialists based in India. Together, they will focus on developing the design and effectively managing the construction of the process plant and associated infrastructure.

Chris Ashton, Worley’s Chief Executive Officer, emphasized the company’s 50 years of experience designing and executing mining projects.

He expressed eagerness to collaborate with Iluka, aiming to deliver the project securely and sustainably, aligning with Iluka’s development objectives and contributing towards the shared goal of fostering a more sustainable world.