Technip Energies has secured a Front-End Engineering Design (FEED) contract for the Viking CCS project, which involves the development of a CO2 transportation and storage network. The project is led by the Harbour Energy-BP Joint Venture and is situated in the Humber, the UK’s most industrialized region with a significant source of CO2 emissions.

The initiative is anticipated to be a key player in establishing a leading Carbon Capture and Storage (CCS) sector in the UK, aligning with the government’s objective of achieving net-zero emissions by 2050.

Viking CCS - Project Details

Formerly known as V Net Zero, the Viking CCS is a CO2 transport and storage network in the Humber, the UK’s most industrialized region. It aims to reduce 10 million tonnes of UK emissions annually by 2030 and up to 15 million tonnes by 2035.

The Project is pivotal in establishing a world-leading Carbon Capture and Storage (CCS) industry in the UK, aligning with the government’s net-zero emissions targets.

The Viking CCS initiative will provide the Humber with high-capacity, reliable, low-carbon infrastructure, fostering inward investment, attracting new industries, and safeguarding regional jobs. According to Harbour Energy, the project could deliver over $4 billion of Gross Value added across the regional economies.

As detailed, the Viking project comprises four main components:

- CO2 Capture

- CO2 Transport (Onshore)

- CO2 Transport (Offshore)

- CO2 Injection and Storage

How Carbon Capture and Storage (CCS) works?

Carbon Capture and Storage (CCS) is a technology aimed at mitigating climate change by capturing carbon dioxide (CO2) emissions produced from the use of fossil fuels in electricity generation and industrial processes.

The process involves capturing the CO2 emissions at their source, transporting them to a storage location, and securely storing them underground to prevent their release into the atmosphere. The CCS process typically consists of three main steps:

CCS Stage | Stage Description |

Capture | Involves capturing CO2 emissions from power plants and industrial facilities using technologies like post-combustion, pre-combustion, and oxy-fuel combustion. |

Transport | After capture, CO2 is transported to a storage location via pipelines, ships, or trucks, depending on distance and quantity. |

Injection / Storage | Captured CO2 is injected deep underground into geological formations, such as depleted oil and gas fields or deep saline aquifers, ensuring secure and permanent trapping. |

Viking CCS - Technip Energies as the FEED Contractor

Technip Energies holds leadership positions in Liquefied Natural Gas (LNG), hydrogen, and ethylene, and is establishing market presence in blue and green hydrogen, sustainable chemistry, and CO2 management.

With support from its subsidiary Genesis, Technip will provide Front-End Engineering Design (FEED) services for the CO2 transportation system. This includes the CO2 handling station, onshore and offshore pipelines, and a Not Permanently Attended Installation (NPAI) platform.

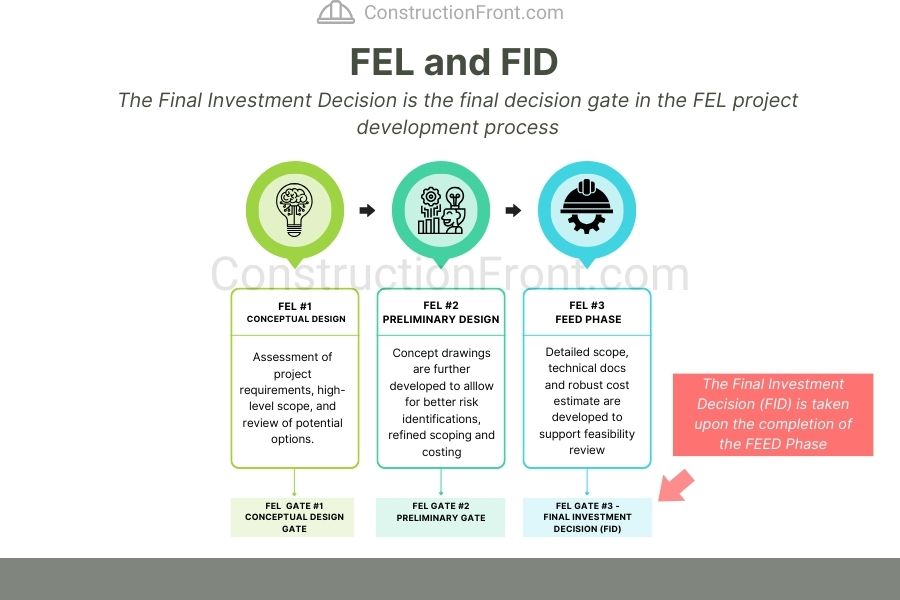

The Front-Eng Engineering Design (FEED) stage is the third and last stage of the Front-End Loading process. It helps project owners (in this case, Harbour Energy-BP JV) to proceed with studies (e.g., detailed scope of works, technical specifications, basic engineering design, robust cost estimates, etc.) that underpin a Final Investment Decision (FID) on whether the project should go ahead.

Charles Cessot, Senior Vice President of Technip Energies Consulting and Products division, expressed pride in supporting the UK’s transition to a more sustainable future.

Cessot expressed excitement about collaborating with Harbour Energy and contributing Technip Energies’ expertise in Front-End Engineering Design (FEED) services to this initiative.

The involvement in the Viking CCS project signifies their commitment to sustainable energy solutions and the reduction of the UK’s carbon emissions.