Tecnimont has secured a Front-End Engineering Design (FEED) contract from MadoquaPower2X to design an integrated green hydrogen and green ammonia plant in the industrial zone of Sines, Portugal.

The MadoquaPower2X project aims to produce green hydrogen using alkaline-water electrolyzer technology and green ammonia through the Haber-Bosch process. The green ammonia will be transported via pipeline to the Port of Sines for export or use as maritime fuel.

MadoquaPower2x – Project Details

MadoquaPower2X, a consortium comprising Madoqua Renewables, Power2X, and Copenhagen Infrastructure Partners (CIP), plans to leverage renewable energy and 1 GW of electrolysis capacity to annually produce 150,000 tons of green hydrogen and 300,000 tons of green ammonia on a large scale.

The project aligns with the highest environmental and safety standards and contributes to economic growth, meeting the EU Taxonomy’s criteria for sustainability and enhancing independent power infrastructure in Portugal’s Sines industrial zone (ZILS).

MadoquaPower2x – Green Hydrogen and Green Ammonia Production

The project employs proven alkaline-water electrolyzer technology for green hydrogen production and the Haber-Bosch process for green ammonia production.

Renewable energy will drive the project, with the electricity primarily sourced from a dedicated renewable energy community. This community includes specific solar and wind assets currently in development in Portugal, ensuring a secure and consistent renewable power supply throughout the project’s lifecycle.

- The produced hydrogen will be conveyed through the local hydrogen grid, providing a versatile energy source for local entities and potentially blending into the natural gas grid.

- Meanwhile, green ammonia will be transported via pipeline to the Port of Sines for export or maritime fuel use, presenting an appealing solution for European green fertilizer manufacturing.

Related Project and News – Green Energy Projects in Europe

MadoquaPower2x and Tecnimont – FEED Contract

The award of this FEED contract follows a prior PRE-FEED conducted by NextChem Tech, MAIRE’s Sustainable Technology Solutions subsidiary, showcasing the collaborative strengths and cross-disciplinary approach underpinning MAIRE’s position as a leading Integrated Technology and E&C solutions provider.

Tecnimont’s responsibilities encompass the design of:

- Integrated electrolyzers,

- Air separation units for nitrogen production,

- Ammonia production plants, and

- Associated storage and ship-loading facilities.

FEED, FID, Notice to Proceed, and EPC

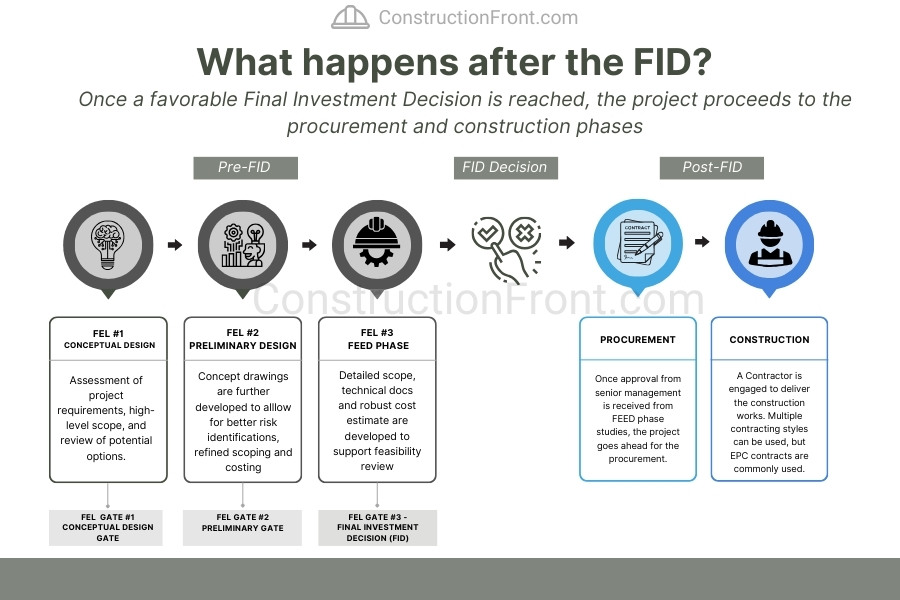

Typically, FEED agreements include specific clauses that grant the owner (in this case, MadoquaPower2x) the discretion to exercise an option, choosing to appoint the FEED Contractor as the EPC Contractor if the project advances to a favorable Final Investment Decision (FID).

When activated, these clauses aim to maintain continuity and capitalize on the familiarity gained with project details, ensuring a smooth transition with minimized risks and streamlined decision-making.

As the EPC contractor, having been engaged in the initial design, there is an opportunity to optimize construction plans, improve design quality, and uphold cost efficiency.

This transition is often formalized through a Notice to Proceed (for construction), where the owner officially instructs the FEED Contractor to assume the role of the EPC contractor and proceed with the construction works.