Aker Solutions has secured a front-end engineering and design (FEED) contract from Hafslund Oslo Celsio (Celsio) to design the CO2 terminal for intermediate storage and export to ships at the port of Oslo, Norway.

The FEED contract has beeen awarded as part of Celsio’s cost reduction initiative for the Oslo CCS (Carbon Capture and Storage) project, which will support the CO2 capture processes at the Celsio waste-to-energy facility in Klemetsrud.

The transitional CO2 storage facility at the port of Oslo will be designed for loading onto ships, facilitating the transport of captured CO2 to the Northern Lights terminal at Øygarden on the west coast of Norway.

Celsio's Waste Incineration Plant at Klemetsrud and the CCS Project

Celsio’s waste-to-energy plant in Klemetsrud processes household and industrial waste, containing about 50 percent biogenic CO2, offering the potential for negative emissions. The waste incineration plant is a significant contributor to the city’s total CO2 emissions.

The carbon capture project at Celsio provides valuable insights for the European waste-to-energy sector, consisting of nearly 20 facilities in Norway and approximately 500 similar facilities across Europe.

The Celsio CCS project, along with the Northern Lights storage, is part of Longship, the Norwegian Government’s carbon capture and storage initiative. This initiative also encompasses CO2 capture from Heidelberg Materials’ cement plant in Brevik, where Aker Carbon Capture and Aker Solutions are responsible for delivering the carbon capture plant.

Related Project and News – Carbon Capture Projects

Celsio’s CCS Project in Oslo - Background

Since April 2023, the Celsio carbon capture project underwent a cost reduction phase due to the initial project cost estimate exceeding the allocated investment budget. During this phase, new vendors were introduced to explore alternative solutions aimed at reducing costs.

Following a concept study, Aker Solutions was chosen to conduct the Front-End Engineering and Design (FEED) for the CO2 terminal at the port of Oslo, with the potential for a subsequent Engineering, Procurement, Construction, Installation, and Commissioning (EPCIC) framework.

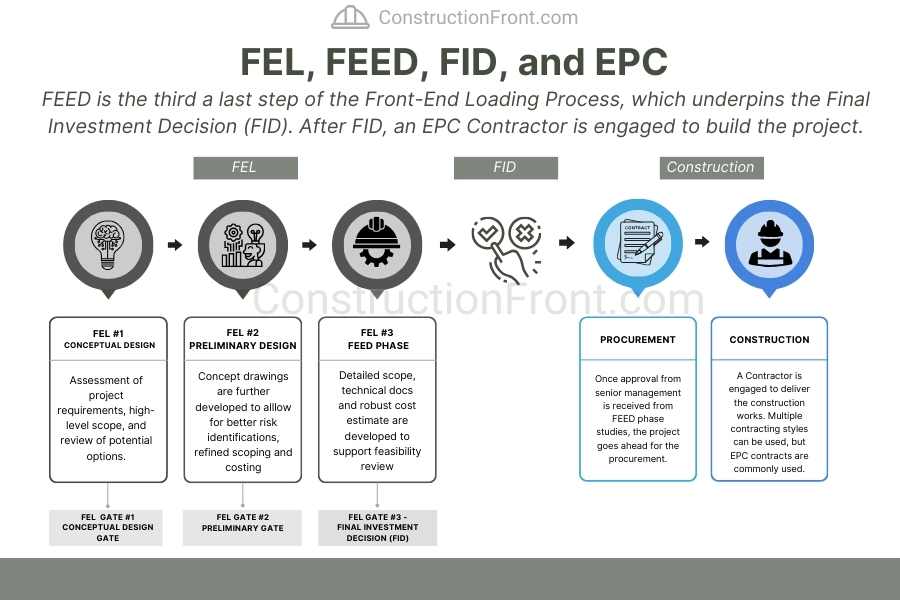

The Front-End Engineering Design (FEED) stage represents the final phase of the Front-End Loading (FEL) process. During this stage, owners develop crucial documents such as detailed scope of works, technical specifications, basic engineering design, and accurate cost estimates.

These documents serve as the foundation for the final round of feasibility studies, providing essential insights before a final investment decision is made and a contractor is engaged.

Celsio’s CCS Terminal in Oslo – Aker as the FEED contractor

Henrik Inadomi, Executive Vice President of New Energies at Aker Solutions, expressed the company’s commitment to supporting customers across the entire Carbon Capture and Storage (CCS) value chain.

He highlighted Aker Solutions’ track record in providing innovative solutions for CCS developments worldwide and emphasized the collaboration with Celsio. Inadomi stated, “We are proud to have engineered a cost-efficient and effective layout, enabling Celsio to proceed with the next phase of this landmark development.”

Knut Inderhaug, Managing Director at Hafslund Oslo Celsio, acknowledged the significance of Aker Solutions’ involvement in the second phase of the FEED for their carbon capture project.

He noted that while the decision on CO2 transportation is a crucial step, challenges remain, including the need for improved framework conditions and income potential before the realization of carbon capture in Oslo.

Related Project and News – Nordic Countries

- Skanska selected to deliver a 1.3B SEK (125M USD) road in Trøndelag County, Norway

- Infranode’s partner Alight signs a PPA with H&M Group

- Infranode acquires 49% in two biogas assets from the Danish operator Renegas

- Nordex secures order to supply 80 Turbines to Renewable Power Capital in Sweden

- DIF Capital Partners Leads €250 Million Funding Round Expand Optical Fibre Rollout in Finland