Verdagy, a leading company in clean hydrogen electrolysis, has appointed Black & Veatch as the Front-End Engineering Design (FEED) contractor for its 60-megawatt (MW) clean hydrogen project in Texas.

This facility, located near the Gulf Coast, aims to produce over 9,000 tons of clean hydrogen annually. The FEED phase is expected to conclude by May 2025, with a Final Investment Decision (FID) and Notice to Proceed anticipated for July 2025.

Project Details - The new Clean Hydrogen Plant Details

The project will deploy Verdagy’s proprietary eDynamic® electrolyzers, designed to offer a broad dynamic operating range. These electrolyzers will adjust to real-time energy fluctuations in the ERCOT grid, enhancing grid resilience while optimizing hydrogen production.

The technology is compliant with both Renewable Fuels of Non-Biological Origin (RFNBO) standards under the European RED III framework and 45V regulations under the U.S. Treasury guidelines.

Verdagy’s electrolyzers are designed and manufactured in the U.S., fostering job creation across the domestic supply chain. The company also operates a hydrogen production plant and R&D facility in Moss Landing, California, where it continues to refine its electrolysis technologies.

Clean Hydrogen and its applications

Clean hydrogen, often referred to as green hydrogen, is produced through electrolysis using renewable energy sources such as wind, solar, or hydropower. Unlike hydrogen derived from fossil fuels, clean hydrogen generates minimal or no carbon emissions, making it a crucial component in the transition to sustainable energy.

Clean hydrogen has a wide range of applications across industries:

- Industrial Processes: Used in refining, ammonia production, and steel manufacturing to reduce carbon footprints.

- Energy Storage: Helps store excess renewable energy, balancing supply and demand in power grids.

- Transportation: Powers fuel cell vehicles, including buses, trucks, and even maritime vessels.

- Power Generation: Can be used in gas turbines and fuel cells to generate electricity with low emissions.

As the hydrogen economy evolves, projects like Verdagy’s Texas facility will play a key role in expanding clean hydrogen’s adoption and integration into global energy market

Black & Veatch as the FEED Contractor

Black & Veatch, a global leader in engineering, procurement, construction, and consulting, brings extensive expertise in infrastructure development, gas storage, processing, and hydrogen electrolysis projects. This collaboration is set to advance the hydrogen industry and contribute to U.S. energy exports.

“We’re excited to tap Black & Veatch with its deep domain expertise for this FEED study,” said Verdagy President Rahul Bammi. “This project will bring over $150 million of investment to Texas, increase U.S. energy exports, create American jobs, and be the precursor to over a gigawatt of upcoming projects in the state.”

Anand Pattani, vice president and managing director of Energy Majors at Black & Veatch, highlighted the company’s experience: “We will utilize this expertise as we support Verdagy on this project, which will help develop the U.S. energy industry and strengthen U.S. energy exports.”

What is FEED?

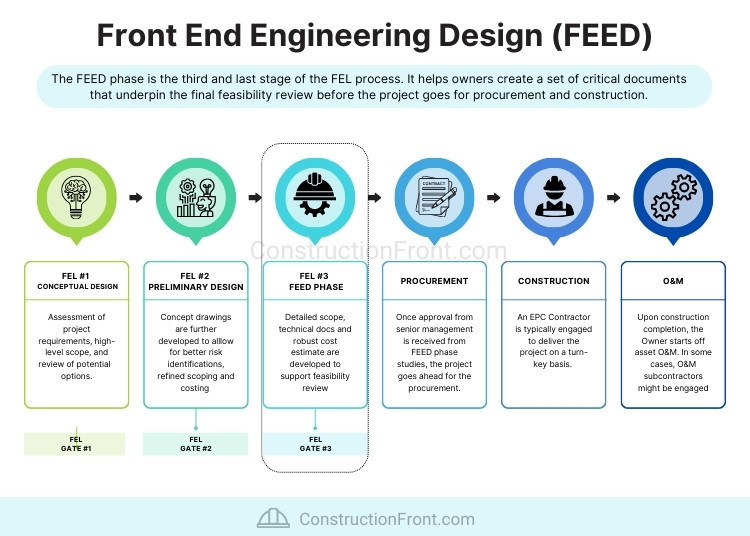

Front-End Engineering Design (FEED) is the third and last stage of the FEL (Front-end Loading) process, which helps owners create critical documents (e.g., detailed scope of works, technical specifications, basic engineering design, robust cost estimates, etc.) that underpin the last round of feasibility studies before the project goes to procurement and construction phases, typically under an EPC Contract.

Related Project and News – Green Energy Projects under FEED Stage

- Técnicas Reunidas to Lead Engineering for La Robla Green Methanol Project

- Tecnimont awarded FEED contract for a green hydrogen / ammonia plant in Portugal

- Technip will be the FEED Contractor for the Viking CCS project from Harbour Energy-BP JV

- Mitsubishi-Worley JV secures FEED Contract for Padeswood CCS Project in the UK