Fluor Corporation secured an EPCM (engineering, procurement, and construction management services) contract for the world’s inaugural renewable hydrogen-based integrated ‘green steel’ mill in Boden, Sweden, owned by H2 Green Steel.

The announcement of the EPCM Contract follows the confirmation of H2 Green Steel’s debt financing agreements for the new plant in January 2024. The project secured €4.2 billion in project financing and raised an additional €300 million in equity. The total equity funding is estimated at €2.1 billion, and the company received a €250 million grant from the EU Innovation Fund.

H2 Green Steel – The World’s First Renewable Hydrogen-Based Integrated Steel Mill

H2 Green Steel, established in 2020, is leading a major global initiative to address climate impact. The company aims to decarbonize challenging industries, beginning with producing steel that achieves up to 95% lower CO2 emissions than traditional coke-fired blast furnaces.

By replacing coal with green hydrogen, generated using fossil-free electricity, the primary emissions from the new plant will shift to water and heat. This transformative approach in the steel industry is just the beginning, and H2 Green Steel’s expertise in green hydrogen positions them to drive decarbonization across other heavy industries.

Related Project and News – Green Hydrogen Projects

H2 Green Steel – Project Status

The construction of Boden’s flagship green steel plant, incorporating integrated green hydrogen and green iron production, is advancing. The video below shows the progress of works as of February 2023.

According to H2 Green Steel, contracts for hydrogen, iron, and steel equipment supply are already in place. A substantial portion of the necessary electricity has been secured through long-term power purchase agreements.

Additionally, half of the initial annual volume of 2.5 million tonnes of near-zero steel has been sold through binding agreements with customers spanning five to seven years.

H2 Green Steel – Fluor as the EPCM Contractor

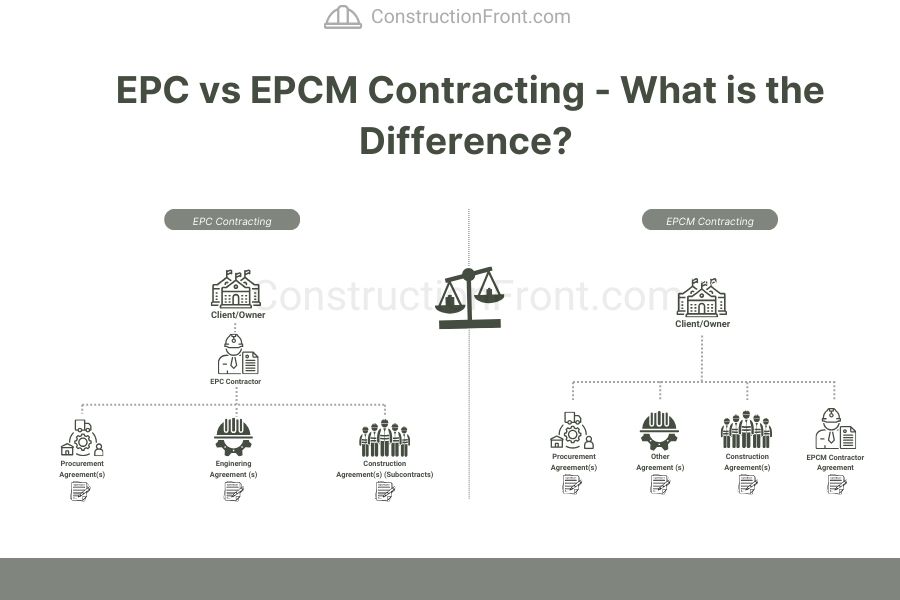

As the EPCM Contractor, Fluor’s responsibilities encompass the melt shop, casting, rolling, and finishing facilities for the steelmaking plant within the H2 Green Steel project. Unlike EPC (Engineering, Procurement, and Construction) agreements, EPCM (Engineering, Procurement, and Construction Management) contractors typically do not assume construction risks.

Their primary responsibilities are usually tied to engineering and detailed design development, assisting in creating procurement packages and overseeing construction management on behalf of the owner (in this case, H2 Green Steel). In essence, the role of an EPCM Contractor is comparable to that of an advisor or professional services contractor.

Suggested Reading: EPC vs EPCM Contracts – What is the difference?

H2 Green Steel – Fluor as the EPCM Contractor - Leadership comments

Harish Jammula, President of Fluor’s Mining & Metals business line, expressed enthusiasm about Fluor’s involvement, highlighting the company’s longstanding presence in the steel industry, expertise in innovative and low-emission steelmaking technologies, and robust footprint in Europe. He emphasized Fluor’s commitment to supporting H2 Green Steel in their pursuit of sustainable steel production.

Related Project and News – Nordic Countires