Different pathologies can affect reinforced concrete. Albeit the most famous one is probably honeycomb, normally associated with inadequate concrete vibration during the pouring process, cold joints are also very frequent on construction sites.

But do you know what concrete cold joints are?

A cold joint in concrete is an area or surface with a structural discontinuity caused by the delayed concrete pouring between two layers of concrete. The delayed placement prevents full integration and knitting between the concrete batches and might lead to reduced structural robustness, increased water permeability, and, in some cases, structural instability.

In this article we will explore this pathology further and understand its main causes, consequences and how to deal with and prevent them.

What is a Cold Joint in Concrete?

Cold joints occur when a fresh concrete batch is poured against a partially hardened existing layer. As you know, concrete hardens through chemical reactions between cement aggregate, water, and air.

Whilst the hardening process is essential to ensure structure stiffness, it also significantly decreases the mix’s intermingling capacity with new fresh batches. The lack of proper bonding between two sections can lead to weak points in the structure, compromising its overall integrity.

The longer the period between the placement of the adjacent layers, the higher the risks of a cold joint. A common sign of a cold joint is a pouring line with different colour tones (refer to the picture below).

How Long can Concrete Sit before a cold joint forms?

As a rule of thumb, we recommend that the time gap between the two batches does not exceed 30 minutes. Technically speaking, other factors can influence this time horizon, such as local temperature, type of cement used, concrete mix, etc.

If you are working with concrete suppliers, plan and avoid last-minute surprises, such as traffic and delays in releasing agitator trucks. If you are working on a small-scale project where the concrete mix is produced on the construction site, it is worth having a backup mixer, especially if you pour important structural elements, such as slabs and beams.

What Are the Causes of Cold Joints?

The main causes are detailed in the table below:

Causes of Cold Joints in Concrete | Description |

Time Gap Between Concrete Pours |

|

Inadequate Concrete Consolidation |

|

Temperature Variations |

|

Improper Construction Sequence |

|

Author’s Note: Typically, cold joints occur in construction sites due to pouring delays, which might lead to significant repair costs and potential project delays. When pouring significant volumes or critical elements (e.g. elements that bear tension loads, such as beams and slabs), it is worth having backup plans, such as a portable concrete mixer, concrete vibrators, and pumps on site.

What are the Consequences of Cold Joints in Concrete Structures?

There are different consequences of cold joints in concrete structures. They will vary depending on the specific application, desired outcome, and load-bearing conditions. The potential consequences and impacts on your structure are detailed below:

Consequence | Impacts | Comments |

Increased Risk of Water Intrusion, and Greater Vulnerability to Cracking | Corrosion, Mold growth, and Progressive deterioration |

|

Diminished Aesthetic Appeal | Visual discontinuity |

|

Structural Discontinuity, Settlement, and reduced strength | Lower load-bearing capacity, Uneven surfaces, misalignments, potential instability |

|

How to Fix a Cold Joint in Concrete?

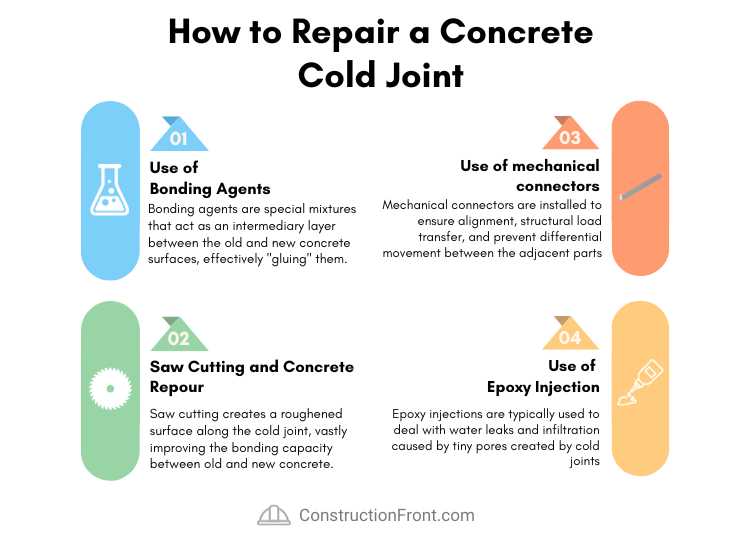

As detailed above, the consequences of cold joints can be severe and lead to significant repair costs. It would be best to address them promptly to mitigate impacts on long-term concrete durability. Some of the potential measures for fixing cold joints are:

Suggested Article: How to Repair a Cold Joint in Concrete? (Effectively!)

Aesthetic Fixes

- Saw-cut and re-pour: Cut along the cold joint, remove deteriorated material, and pour fresh concrete for a visually seamless appearance.

- Overlay or resurfacing: Apply a new layer of concrete or mortar over the cold joint to create a uniform surface and improve aesthetics.

Structural Fixes

- Epoxy injection: Inject epoxy resin into the cold joint to fill gaps and enhance bonding, restoring structural integrity (Expoxy injection can be expensive).

- Mechanical connectors: Installation of dowel bars or tie bars across the joint to transfer loads and prevent differential movement (Best to ensure structural stability)

Water Infiltration Fixes

- Joint sealing: Apply specialised sealants to the cold joint to prevent water infiltration and protect against moisture-related damage.

- Waterproofing coatings: Apply coatings or membranes over the joint area to create a waterproof barrier and prevent water penetration.

FAQ

How do I know if my concrete structure has a cold joint?

Some of the visual signs are:

- Visible line or seam – Cold joints often appear as clear and visible lines or seams on the surface of the concrete

- Differences in texture or colour – variations in texture or colour are easily spotted when compared to the surrounding area.

- Structural anomalies – Cold joints can contribute to structural anomalies, such as uneven settlement and cracking. Both may become more apparent as time passes, and you should consult with a structural engineer to address them

Apart from visual inspections, there are also non-destructive tests (such as the ground-penetrating radar), core sampling, load testing, and thermography, which can indicate the presence of failed joints.

How to prevent cold joints in concrete?

You should:

- Plan your pouring at least a week in advance (check the weather forecast, develop a pouring plan, and calculate the total volume of concrete required)

- Have backup equipment, such as concrete mixers, vibrators, concrete pumps, etc.

- Ensure continuous concrete placement

What is the difference between cold and construction joints?

The table below summarises the differences between cold and construction joints.

Characteristics | Cold Joint | Construction Joint |

Purpose | Unintentional joint formed due to concrete placement delay (Construction Error) | Intentionally created joint for construction convenience |

Formation | Delayed placement of fresh concrete | Planned interruption between concrete placements |

Strength | Weaker than a properly bonded concrete section | Structurally sound with reinforcement and proper alignment |

Appearance | Visible seam or line | Neat and controlled joint with clean break between sections |

Waterproofing | More prone to water infiltration | Can be designed for improved water resistance |

Load Transfer | Limited load transfer capability | Designed to facilitate load transfer between sections |

Planning and Design | Considered a construction error | Part of the construction plan and detailing |

Remediation | Difficult to repair or eliminate completely | Remediation options available based on joint type |

Suggested Article: Are Concrete Expansion Joints necessary? (Click here)

Conclusion

Cold joints might lead to serious issues related to the durability, structural integrity, and aesthetic appeal of concrete structures. Overall, these joints occur when there is a delayed pouring of fresh concrete against a partially hardened existing layer.

Fixing cold joints can be expensive and time-consuming. Therefore, we advise you to thoroughly plan your pouring activity and eliminate all the risks of this undesired pathology.