The initial development of complex engineering projects, such as oil rigs, manufacturing, mining and energy plants, is typically associated with various challenges, such as creating extensive technical details and specifications, assessing constructability, identifying essential resources, supply chain risks, and many others.

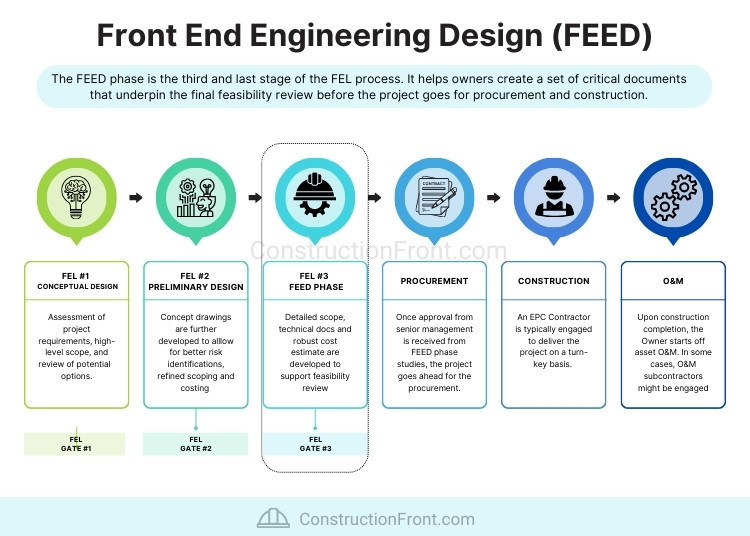

One of the well-known methodologies to further study and solve these is what is called the Front-End Loading (FEL) planning process, which is typically split into three stages:

- Stage 1 – Conceptual Design

- Stage 2 – Preliminary Engineering

- Stage 3 – Front-End Engineering Design

The Front-Eng Engineering Design (FEED) stage is the third and last stage of the FEL process. It helps owners create critical documents (e.g., detailed scope of works, technical specifications, basic engineering design, robust cost estimates, etc.) that underpin the last round of feasibility studies before the project goes to procurement and construction phases.

In this article, we will explore the FEED phase further, understand its importance for de-risking projects, check some project examples, and discuss the pros and cons of this approach.

What is the Front-End Engineering Phase (FEED) Phase?

The Front-End Engineering Design (FEED) Phase is the third and last stage of the Front-End Loading (FEL) planning process, which consolidates the outcomes from FEL Stage 1 and 2 into a set of documents, which include (but not limited to):

- A detailed design package and scope of works,

- Technical schedules and specifications,

- Robust cost estimates, and

- All documents required to proceed for project’s procurement.

The typical division in the Front-End Loading (FEL) process involves three stages outlined in the table below. It is a gate-staged process, implying that at the conclusion of each phase, there is a review of the outcomes, and a decision is made on whether the project should proceed to the next stages.

FEL Stages | Details and Purpose | Key Outcomes |

Stage 1 – Scoping Study / Conceptual Design |

|

|

Stage 2 – Feasibility Study / Preliminary Engineering |

|

|

Stage 3 – Front-End Engineering Design / Project Definition |

|

|

Author’s Note: The name of stages, purposes, and outcomes might vary slightly according to the industry, project niche, or project location. For example, a similar process is undertaken in infrastructure/civil construction projects in Australia via an early contractor involvement” framework – click here for further details. In Canada, some Public Private Partnership projects have been using what is called a “Progressive Procurement Strategy”, which has similar features.

Upon successful completion of the three stages, the project will usually be submitted for senior management/board review, and a final investment decision (FID) is made. If the company decides to go ahead with the project, it will typically proceed to procurement/tendering phase and, subsequently, to the construction and operation stages, as detailed in the picture below.

Owners commonly choose the EPC (Engineering-Procurement-Construction) contracting/procurement framework for most projects with significant CAPEX and technical complexities. This is because this approach transfers almost all the construction risks to the EPC Contractor.

What are the deliverables of the Front-End Engineering Design phase?

The specific deliverables of the FEED phase will vary according to the type of project, industry, and company practices. However, standard deliverables typically include several documents across categories, such as:

Project Definition Documentation:

- Project Scope Document: Clearly outlines the project objectives, scope, constraints, and assumptions.

- Project Execution Plan: Describes the overall strategy for project execution, including timelines, resources, and key milestones.

Process Design Documents:

- Process Flow Diagrams (PFDs): Illustrate the overall process flow, major equipment, and key process parameters.

- Piping and Instrumentation Diagrams (P&IDs): Detail the process flow, piping, instrumentation, and control systems.

- Heat and Material Balances: Provide calculations for heat transfer and material usage.

Equipment and Instrumentation Specifications:

- Equipment Specifications: Detail specifications for major equipment, including design criteria and performance requirements.

- Instrumentation Specifications: Define the specifications for instruments and control systems.

Civil and Structural Design Documents:

- Site Layout and General Arrangement Drawings: Illustrate the layout of major facilities and structures on the site.

- Civil and Structural Specifications: Detail specifications for civil and structural components.

Mechanical and Piping Design Documents:

- Mechanical Equipment Layouts: Show the placement of major mechanical equipment.

- Piping Layouts and Isometrics: Detail the arrangement of piping systems.

Electrical and Instrumentation Design Documents:

- Electrical Single Line Diagrams (SLDs): Illustrate the electrical distribution system.

- Instrument Loop Diagrams: Provide details on instrument loops and connections.

Safety and Environmental Documentation:

- Hazard and Operability (HAZOP) Studies: Identify and assess potential hazards and operability issues.

- Safety Data Sheets (SDS): Document the properties and hazards of chemicals used in the project.

- Environmental Impact Assessment (EIA): Assess and document potential environmental impacts.

Cost Estimates:

- Updated Cost Estimate: Provide a more detailed and accurate estimate of the project costs based on the refined design.

Project Schedule:

- Updated Project Schedule: Outline the sequence of activities, timelines, and dependencies for the project.

Risk Assessment and Mitigation Plans:

- Risk Register: Identify and assess project risks, along with mitigation plans.

- Contingency Plans: Outline strategies for addressing potential issues during project execution.

Regulatory Compliance Documentation:

- Permitting and Regulatory Compliance Documentation: Ensure that the project complies with relevant laws and regulations.

Front End Engineering Design (FEED) – Project Examples

Some recent and relevant projects that use FEED are detailed below:

- Bechtel to provide front-end engineering (FEED) services for Urenco’s uranium processing facility in the UK (click here to read more details) – Bechtel has secured a Front-End Engineering Design (FEED) contract to support Urenco in the expansion of its Tails Management Facility (TMF) in the UK.

- Fluor to provide front-end engineering and design services for Swedish Battery Developer Altris AB (Click here to read more details) – Altris AB has selected Fluor’s Advanced Technologies & Life Sciences business line to provide front-end engineering and design (FEED) services for the world’s inaugural industrial-scale sodium-ion battery production facility in Sandviken, Sweden.

When FEED Contracts are commonly used?

As seen in the examples above, within the construction industry, the FEL process and FEED phase are commonly associated with large-scale “ad-hoc” industrial projects with significant implementation risks.

Owners are willing to take on board advice from an experienced engineering firm or contractor to de-risk and optimise project delivery.

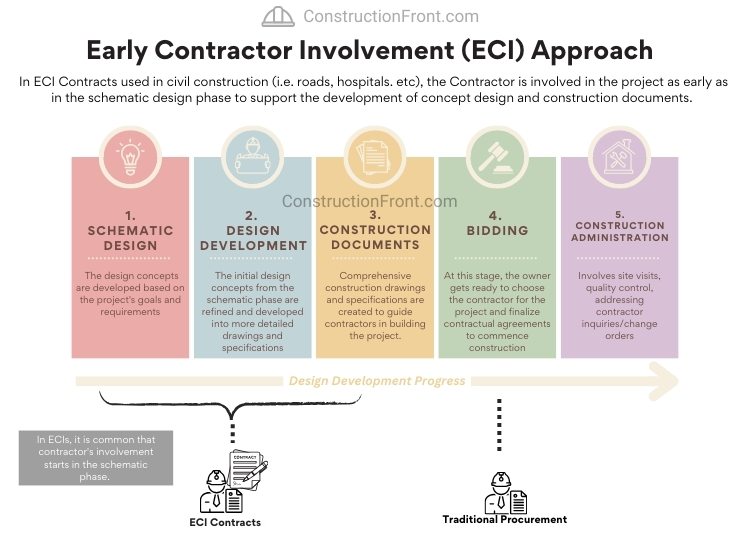

In civil construction (i.e. construction of roads, stadiums, etc.), a similar approach can be used by owners to help in project development – the early contractor involvement framework.

This approach enables the contractor to provide valuable insights and expertise to the client/owner from the project’s inception, helping them to develop the project’s concept and design through to the construction phase (a high level overview of ECI Contracts is detailed below).

Some recent examples of ECI agreements are:

- CPB Contractors selected for upgrades in two RAAF Bases in Western Australia under a ECI Contract

- Infrastructure Ontario uses the Progressive Procurement Strategy for new Hospital PPP in Ottawa (Canada)

- CPB-Georgiou JV will be the construction partner for Paradise Dam Wall Replacement Project in Queensland (Australia)

Why is the FEED Phase important?

Research from the Construction Industry Institute (CII) indicates that thorough front-end planning can lead to, substantial decreases in project cost, uncertainty around project’s schedule, and operational variability, and an increased probability of meeting a project’s environmental and social goals.

The Institute emphasizes that Front-End Loading (FEL) is a pivotal factor for the success of complex engineering and construction projects. Its studies also provide a general guideline that the cost of Front-End Planning (FEP) is typically around 2.5% of the total project cost. However, this investment tends to yield an average of 10% cost savings, a 7% reduction in scheduled delivery time, and a 5% decrease in changes during the project.

Front-end Engineering Design Phase - Pros and Cons

FEED Advantages

Among the many advantages, it is worth highlighting:

- Advantage #1 – Project Definition – FEED allows for a clearer understanding of the scope needs/objectives, requirements and constraints (decreased risk of scope creep and/or gold plating). Also, technical documents and specifications created during the FEED phase provide greater certainty that the project will reach the desired outcomes.

- Advantage #2 – Enhanced Risk Identification and Mitigation – Early identification of potential project-wide risks, such as technology and resource availability, allows for proactive mitigation strategies. Also, the stage-gated embedded in the FEL and FEED processes allows for risks and issues to be reviewed before substantial investments are made.

- Advantage #3 – Cost Savings: When properly done, FEED might help with lower lifecycle costs, increased budget certainty and construction schedule, and decreased need for changes during later phases, which are usually costly. This study undertaken by researchers from Arizona University found that projects with high FEED accuracy significantly outperformed projects with low FEED accuracy in terms of cost increase.

- Advantage #4 – Detailed Feasibility Assessment: Detailed feasibility studies are conducted to assess technical, economic, and legal viability, providing senior management with a clear understanding of the project for an informed decision-making process.

FEED Disadvantages and Risks

Even though the benefits of FEED most certainly outweigh its drawbacks, it is worth noting that:

- Cons/Risks #1 – FEED is time-consuming – The FEED phase can be time-consuming (sometimes lasting from 12 to 24 months, depending on project complexity), potentially delaying the start of detailed design and construction.

- Cons/Risk #2 – Upfront Costs: A significant upfront investment in engineering and analysis is required before detailed design and construction activities begin, and owners might have increased expenditure levels.

- Cons/Risk #3 – Flexibility vs. Rigidity: While the early identification of risks is advantageous, there’s a balance between flexibility for changes and the need to finalize project details. Further, there is also a risk of over-designing or over-engineering in an attempt to account for all potential uncertainties.

- Cons/Risk #4 – Uncertainty in Market Conditions: Economic and market conditions may change between the FEED phase and the subsequent stages, affecting project viability.

FEED Contracts - Key Features

Given the nature of the services (technical and commercial advice), FEED Contracts will typically use models akin to consulting agreements, where the FEED Contractor will be remunerated as the project progresses.

The remuneration can be made via:

- cost-plus-fee schemes (open-book basis),

- hourly rates according to the resource used,

- lump-sum payments for milestone achievements, such as the approval of major deliverables (e.g. detailed scope of works), or

- other variations that suit the owner and the FEED provider.

FAQ - Front-End Engineering Design

What is the FEED endorsement Clause in EPC Contracts?

This FEED Endorsement Clause specifies that the EPC contractor takes on complete responsibility for the technical accuracy of the FEED, which the owner supplies.

FEED Design vs Detailed Design - What is the difference?

The table below summarises the key differences between them.

| Aspect | FEED Phase | Detailed Design Phase |

|---|---|---|

| Purpose | Establish project scope and feasibility. | Develop detailed engineering for construction. |

| Objectives | Develop conceptual understanding, identify risks. | Provide precise specifications, minimize changes. |

| Level of Detail | Higher-level overview with flexibility for changes. | Granular and detailed, with fewer changes allowed. |

| Cost Estimation | Preliminary estimate refined in Detailed Design. | Refined estimate based on detailed engineering. |

| Timeline | Shorter phase preceding Detailed Design. | More time-consuming, follows FEED phase. |

| Key Deliverables | Project definition, conceptual designs, preliminary specifications. | Detailed drawings, finalized specifications, equipment lists. |

Need Help?

Do not hesitate to contact us (click here) for specialised advice in construction industry.