If you have ever worked in construction projects involving long concrete pavement sections, such as highways, you might have come across a concrete keyway joint. But what is it specifically?

Keyways joints in concrete are an intentional gap created between two structural elements, in which one part of the structure act as a coupler and the other piece has a matching “key” to ensure the mechanical/structural connection between the blocks.

They are normally implemented to facilitate load transfer and avoid excessive cracking. This article will further discuss this kind of joint, understand when and why they are used in civil structures, their pros and cons, and other relevant features, such as materials usually used.

What is a Keyway Joint in Concrete?

Keyway joints are structural joints normally created with a prefabricated u-shape galvanised steel or metal piece with flanges, which is placed in the structure before concrete pouring (see below).

From a structural and design standpoint, they are essential to ensure load transfer between adjacent concrete structures (i.e., pavement blocks) and can be used in conjunction with dowels (click here to read our article on concrete dowels) to provide additional support in the joint area.

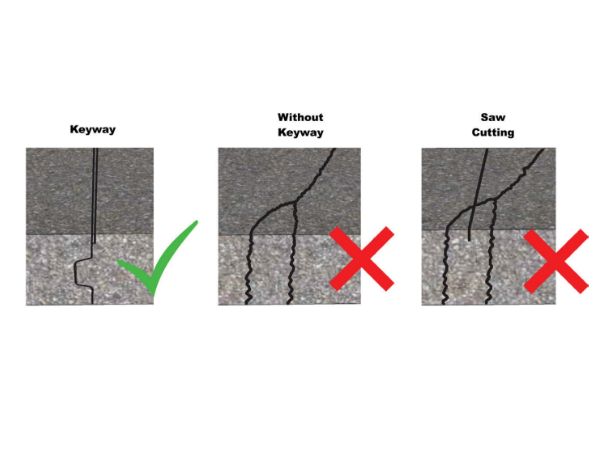

They allow independent movements between adjacent pieces and significantly reduce the probability of concrete cracking.

The joints are often placed at predetermined locations to create planned breaking points in the structure and help to regulate tensions arising from concrete expansion and contraction.

Depending on the specific project and design requirements, they can be shaped in different ways, including trapezoidal, rectangular, or dovetail.

Why and When are Keyway Joints Used in Concrete?

These joints can be used in different construction projects but are commonly seen on concrete highways, bridges, and large slabs, which are exposed to signficant temperature gradients that can lead to expansion and contraction.

The table below summarises why and when this approach can be used.

| Why | When | Rationale for their Use |

|---|---|---|

| Facilitate load transfer | Buildings, bridges, retaining walls | Distributes structural load, prevents concentrated stress points, minimizes cracking and failure |

| Control differential movement | Slabs, pavements, foundations | Accommodates changes in temperature, shrinkage, and settling, maintains alignment, prevents damage |

| Accommodate expansion/contraction | Outdoor structures, structures exposed to temperature variations | Allows concrete to adjust without imposing excessive stress, prevents cracking and structural damage |

| Minimize cracking/structural damage | Large concrete surfaces, high-stress areas | Controls movement, relieves stress, minimizes the risk of cracking and damage |

Overall, keyways joints are used in thicker slabs (above 250-300mm), given the construction challenges associated with installing the joints in thinner structures.

Overall, keyways joints are used in thicker slabs than 100mm, given the construction challenges associated with installing the joints in thinner structures.

What are the Prons and Cons of Keyway Joints in Concrete?

We highlighted 5 points with advantages and drawbacks of keyway joints below.

Pros:

- Crack Control: Keyways help prevent uncontrolled cracking in concrete structures, improving their appearance and durability.

- Structural Integrity: By providing load transfer, keyways enhance the overall structural integrity of concrete.

- Cost-Effective: Implementing keyways is a cost-effective solution to avoid potential concrete repairs and maintenance.

Cons:

- Installation Complexity: Creating precise keyways requires skilled labour and attention to detail during the construction process.

- Potential Misalignment: If not properly designed or installed, keyways can lead to misalignment issues between concrete sections.

What are the disadvantages of not using a keyway joint in concrete pavement?

Neglecting the use of these devices may lead to the following:

- Cracking and Damage: The pavement will not be able to accommodate shrinkage, temperature changes, and settling.

- Uneven Surfaces: Your structure may experience uneven settlement, especially in areas with high-stress loads or expansive soils. This can cause discomfort for road users, affecting vehicle stability and potentially leading to accidents.

- Joint Faulting: Joint faulting can create noticeable height differences between slabs, causing a bumpy vehicle ride and increasing maintenance requirements.

- Limited Durability: The structure is much more susceptible to long-term degradation, such as water infiltration and reinforcement corrosion.

Conclusion

Keyway joints are widely used in concrete floors and pavements to facilitate load transfer, accommodate expansion and contraction, and minimize cracking and damage.

Generally, they are made of galvanized steel or metal and can come in different sizes and shapes. The structural engineer will specify its spacing and location to ensure optimal functionality. Contractors and Builders should thoroughly pay attention to their installation to avoid misalignment.

Neglecting the installation of keyway joints (and, more broadly, of any joints) in the concrete pavement can result in various issues, including cracking, uneven surfaces, joint faulting, and reduced durability.