Worley has been awarded a front-end engineering design (FEED) contract for ABEL Energy’s Bell Bay Powerfuels project in Northern Tasmania. ABEL Energy is developing this flagship green hydrogen and methanol project to produce 300,000 tonnes of renewable, green methanol annually.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Bell Bay Powerfuels Project – Green Methanol and Hydrogen

The Bell Bay Powerfuels project will combine green hydrogen from a 240MW water electrolysis plant with synthesis gas from a biomass gasifier to produce green methanol.

The production process will utilize 100% renewable power from hydro and new wind production assets and, fresh water from significant river systems, and biomass residues recovered from existing Tasmanian plantation forestry operations.

The plant aims to operate with minimal environmental impact, boasting virtually zero greenhouse gas emissions, water vapour emissions, or effluent discharge. The production process is odourless, and the resulting product is biodegradable and easy to handle as a clear liquid. Key features of the project include:

- $1.4+ billion investment for Northern Tasmania

- Construction opportunities for 500+ workers

- Direct and indirect employment for 300+ workers for at least 30 years

- Gross regional impact of more than $4.6 billion

- Abatement of 540,000 tonnes per year of CO2

- Local renewable fuel uptake opportunities (ports, rail, ferries, etc)

What is green methanol?

Green methanol is a form of methanol crafted using renewable energy sources and sustainable raw materials like biomass or carbon dioxide extracted from the atmosphere. This production method is designed to curtail environmental impact, presenting a more sustainable and environmentally friendly substitute for conventional methanol, typically derived from fossil fuel.

Green methanol, as a transportation fuel, also contributes to lowering the carbon intensity of the shipping industry. Most of the green methanol produced at the Bell Bay facility is earmarked for consumption by shipping companies, contributing to the avoidance of over 540,000 tonnes of CO2 annually compared to conventional crude oil-based marine fuels.

Related Project and News – Renewable Energy in Australia

Bell Bay Powerfuels Project – Worley as the FEED Contractor

According to Worley, the FEED stage is expected to last 12 months, targeting plant start-up in 2028. In collaboration with the local Tasmanian engineering company, pitt&sherry, Worley will tailor the delivery approach to address the distinctive considerations of the region.

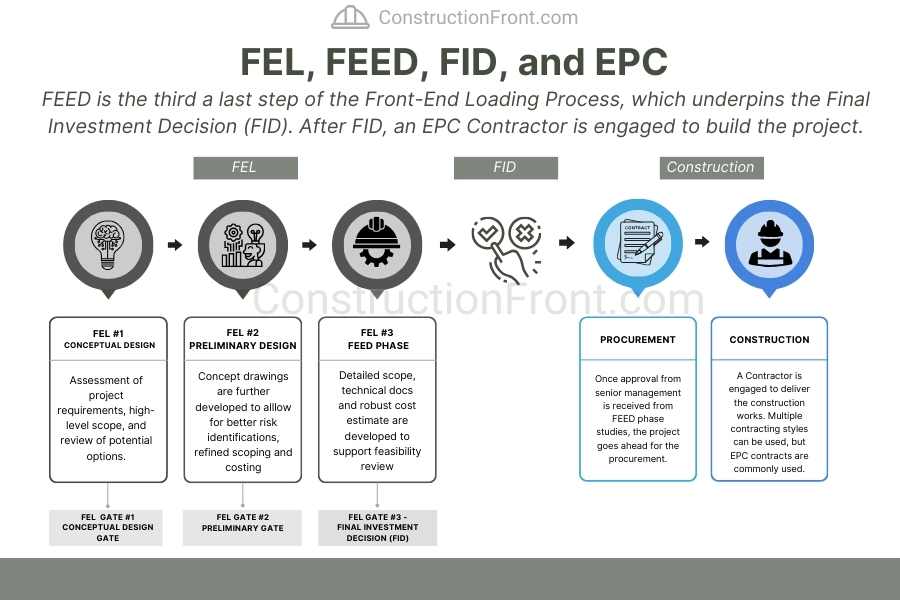

Worley is tasked with overseeing the design, engineering, procurement, and construction services up to the final investment decision (FID). The FEED phase constitutes the third and final stage of the Front-End Loading (FEL) process, generating essential project documents that guide the decision to proceed with construction, including (but not limited to):

- Detailed Scope of Work

- Basic Engineering Documents and Technical Specifications

- Robust Cost Estimate

- Procurement Packages, which may vary based on the contracting approach (e.g., Design-Construct Contract or Engineering-Procurement-Construction Approach)

If projects receive a favourable FID at the end of the FEED stage, an EPC or EPCM Contractor is engaged in executing the construction works, as detailed in the sketch below.