Construction contracts evolve to address industry needs, such as funding and financing requirements, risk appetite, and market conditions. With the recent increased flow of investments in energy projects, construction professionals have implemented different commercial arrangements to deliver these.

Typically, the construction of renewable energy projects is delivered under an EPC (Engineering, Procurement, and Construction) contract between the client and contractor, where the latter assumes the majority of construction risks.

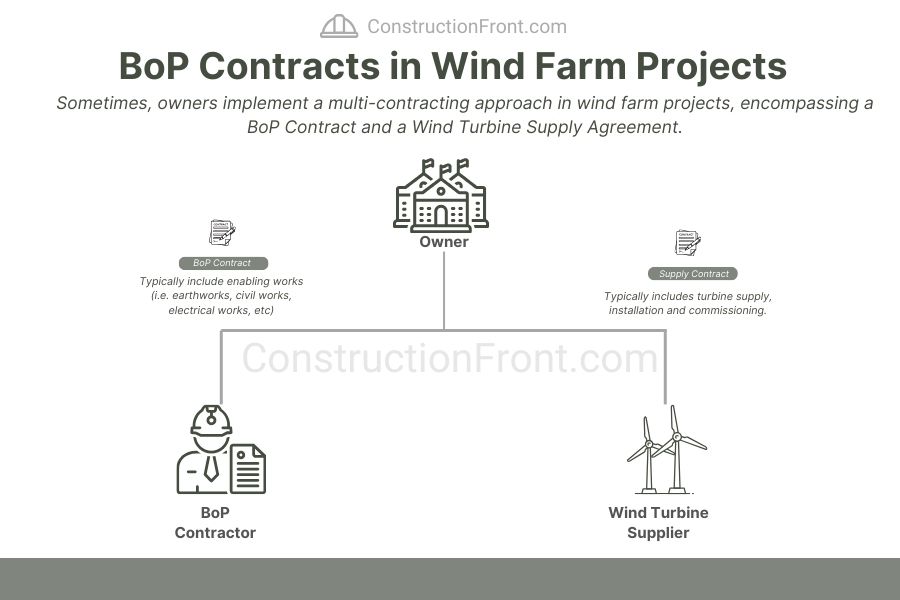

However, for many reasons (including lower costs), owners in some projects split the EPC contract scope into two major agreements:

- a Balance of Plant Contract (BoP);

- and an Equipment Supply Agreement (also named Original Equipment Manufacturer – OEM).

In this article, we will explore the advantages and drawbacks of this commercial approach, understand when and why Balance of Plant (BoP) Contracts are used, their scope, and some other essential features and issues, such as interface risks and project bankability – keep reading.

What is a Balance of Plant (BoP) Contract?

In the energy sector, Balance of Plant (BoP) Contracts are typically associated with all enabling and infrastructure works (e.g. earthworks/marine works, road access construction, foundations, inground cabling, transformers, etc.) required to allow the installation of the power generator, which is supplied by a different party.

BoP contracts have been used in diverse energy projects, including traditional power plants (coal, gas, nuclear), renewable energy projects (wind, solar), hydropower, geothermal, biomass, CHP, and waste-to-energy.

More specifically, in wind farms, Balance of Plant agreements arises as an alternative for owners procuring the turbines from overseas suppliers but wish to deploy a local contractor for the BoP works to comply with local regulations, save costs, leverage experienced from local contractors, and, in some cases, unwillingness of the wind turbine supplier to wrap up all project risks under an EPC Contract.

Suggested Reading: What is an EPC Contract? (Key Features, Examples, and Tips)

What is Typically included in a BoP Contract?

The typical scope of work in a BoP Agreement within the energy industry is multifaceted and encompasses various crucial aspects related to the construction, installation, and integration of diverse components.

While the specific details may vary based on the nature of the energy project, a standard BoP contract might include the following:

Scope of Works | Description |

Site Preparation and Civil Works | – Clearing and grading the site. – Excavation and foundation works for various structures. – Construction of roads, platforms, and other necessary civil infrastructure. |

Structural Components | – Installation of buildings and structures (control rooms, switchyards, etc.). – Erection of support structures for equipment and systems. |

Marine Works (Offshore projects) | – Offshore Logistics and Transport – Cable Laying and Burying – Dredging |

Electrical Works | – Installation of power cables and wiring. – Construction and installation of substation equipment and switchyards. – Grounding and lightning protection systems. |

Instrumentation and Control Systems | – Installation of control panels and systems – – Implementation of instrumentation for monitoring and control – e.g Supervisory Control and Data Acquisition (SCADA) systems – Integration of control systems with the overall plant architecture. |

Mechanical Systems | – Installation of piping and plumbing. – Implementation of HVAC systems. – Integration of fire protection and safety systems. |

Water Systems | – Construction and installation of water supply and treatment systems. – Implementation of cooling water systems for equipment. |

BoP – Testing and Commissioning | – Conducting tests to ensure the proper functioning of all systems included in the BoP package |

Project Management and Documentation | – Project planning, scheduling, and coordination. – Documentation of all activities, including as-built drawings and manuals. |

When is a Balance of Plant (BoP) Contract used? (What are its advantages?)

Several reasons might contribute to owners choosing a multi-contract approach (e.g. BoP Contract + Wind Turbine Supply Contract) instead of an EPC contract, which typically wraps up most of the construction risks.

Some of the reasons and advantages of using a multi-contracting framework are:

- Specialized expertise and improved risk allocation: An owner may prefer engaging multiple suppliers and contractors for the different project packages when the project requires specialized expertise. By doing so, owners have more control over risk allocation since they can select specific suppliers and contractors based on their capabilities and existing relationships (e.g., the owner wishes to engage a local civil contractor with significant experience performing BoP Works).

- Flexibility in Component Selection: Owners may prefer flexibility in choosing specific suppliers for components like turbines, generators, or other specialized equipment, allowing for customization based on project requirements and owner’s preferences.

- Optimization of Costs: By engaging specialized suppliers, owners can optimize costs by negotiating directly with multiple vendors for specific project packages and components.

- Phased Project Implementation: Owners might choose a phased approach, allowing the sequential implementation of different project components based on availability or project priorities (e.g. while still assessing and finalizing wind turbine details, owners can undertake the enabling works with the BoP Contractor)

- Market Depth –

- In-House Project Management Capability: Owners with solid in-house project management capabilities may choose to manage and coordinate multiple suppliers.

Balance of Plant (BoP) Contracts - Risks and Drawbacks

Despite the advantages detailed above, the use of a BoP Contract and multi-contracting framework in an energy project leads to some challenges, risks, and drawbacks that are worth noting, such as:

- Project Financing Challenges: Securing project financing may be more complex in the “BoP + Equipment Supplier” model, as lenders may find it challenging to assess and mitigate risks when dealing with multiple contractors. Lenders may perceive higher risks in this approach when compared to the EPC Turnkey model, particularly regarding interface risks, coordination challenges, and potential disputes, which could impact loan terms and interest rates.

- Interface Risks: Coordinating multiple contractors, especially if the Equipment Supplier and BoP contractor are from different entities or countries, can be complex and may lead to coordination challenges. Furthermore, the interface between the supplier and BoP contractor may introduce risks related to integrating different components, potentially leading to delays or technical issues.

- Complex Contractual Agreements: Drafting and negotiating separate contracts for the BoP and Supplier can be time-consuming and may result in complex contractual agreements.

- Risk Allocation Complexity and Gap Risks: Allocating risks among multiple entities requires careful consideration and negotiation, leading to potential disputes if risks are not clearly defined and managed. Further, There is a potential for responsibility gaps or disputes over accountability for project aspects that fall in the “Gray area” between the scopes of the equipment supplier and BoP contractor.

- Increased Potential for Disputes: Disputes between the supplier and BoP contractor can arise (e.g. delays by one party affecting the other), impacting the overall project timeline and success.

- Project Management Burden on Owner: Owners may bear a heavier project management and coordination burden, as they need to oversee and align activities between the Supplier and BoP contractor.

Author’s Note:

Like public-private partnership contracts (click here for further details), energy projects usually draw private debt via project financing. From a lender’s perspective, splitting a “vanilla” EPC Construction Contract into two or more packages gives rise to significant interface risks (e.g. delays by the BoP Contractor affecting the Equipment Supplier Works), which, in turn, raise multiple concerns with financiers.

BoP Contracts - Project Examples

Example #1 - SunZia Project in New Mexico - USA

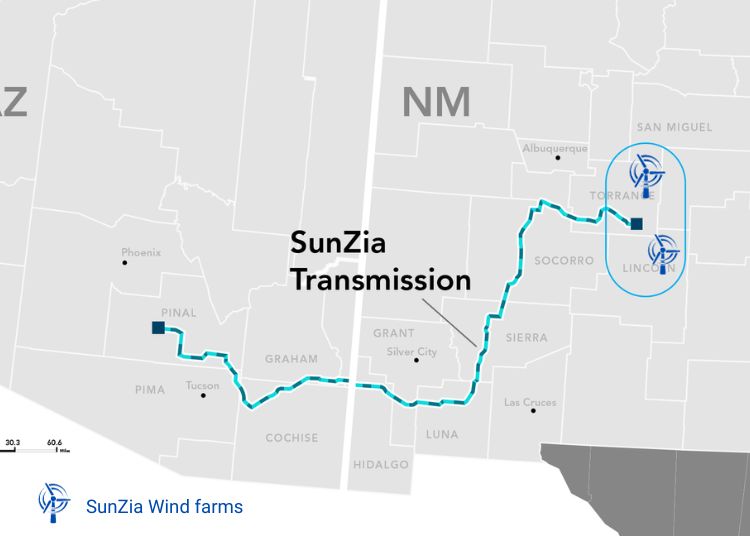

The SunZia project includes the construction of wind farms and transmission lines between central New Mexico and south-central Arizona. The SunZia Project includes two main components (see map below):

- SunZia Wind:This segment involves wind turbines producing over 3,500 MW of new renewable power. The wind farms are situated in Torrance, Lincoln, and San Miguel Counties, New Mexico.

- SunZia Transmission Line:This is a 550-mile ±525 kV high-voltage direct current (HVDC) transmission line connecting central New Mexico to south-central Arizona. Designed with the capability to transport 3,000 MW of clean, renewable energy, it serves as a key transmission infrastructure for the project.

Given the size of the project, multiple agreements were executed by Pattern Energy (owner), contractors and suppliers for project delivery. More specifically, the Sunzia Wind Project included the following arrangement:

Project | BoP Contractor | Wind Turbine Suppliers |

SunZia Wind Project | Blattner Energy (Quanta affiliated company) | GE Vernova, Vestas |

Example #2 - Renewable Power Capital (RPC) wind farms in Sweden

Renewable Power Capital (RPC) is a European renewable energy investment platform established in 2020 and supported by CPP Investments. In late 2023, RPC confirmed the order for 80 wind turbines from Nordex, a German-based manufacturer, for the following projects:

- Vitberget in the Kramfors municipality (161 MW)

- Storhöjden in the Kramfors municipality (154 MW)

- Sörlidberget in the Kramfors and Sollefteå municipalities (140 MW)

- Knäsjöberget in the Sollefteå municipality (98 MW)

Project | BoP Contractor | Wind Turbine Suppliers |

Four Wind farms in Sweden | Non-disclosed | Nordex |

Sources:

- Balance of Plant for Wind Projects (strath.ac.uk)

- Key bankability issues for renewable energy projects (pwc.com.au)

- Electrical Balance of Plant (gegridsolutions.com)

- What is an EPC Contract? (Key Features, Examples, and Tips)

- Guide to an offshore windfarm

- Wind Farm Contracting – Is it time to split from EPC?