Concrete dowels are commonly used on construction sites, especially when concrete structures are being built. Albeit that, many construction professionals still need to become more familiar with them and/or what they are used for.

So, in a nutshell, what are dowels in concrete? Overall, concrete dowels are structural elements that connect concrete sections, facilitating proper alignment, load transfer, and prevention of differential movement between different parts of the structure. Their use and correct placement contribute to the structure’s stability and durability.

In this post, we will further understand what they are, when and why they are used, their different types, and their common applications.

What are dowels in concrete?

Dowels are normally bars or rods which are introduced into drilled holes in existing concrete sections. Overall, they enable load transfer between slabs and prevent the development of cracks due to slab movement.

They are typically made of materials like steel or stainless steel, and their specifics may vary according to the design requirements (strength, dimensions, durability, and corrosion resistance). For example, it is prevalent to use epoxy-coated dowels in environments with high.

According to this interesting study published Institute of Physics on the importance of dowels in transversal joints in concrete pavements, dowels are placed in transversal contraction or construction joints of concrete pavements and help to transfer loading between individual slabs.

Structural engineers carefully design them and take into consider consideration factors such as joint spacing, diameter, and dowel length.

When and Why to Use Dowels in Concrete?

These components are used in different scenarios, such as:

- Expansion Joints: Dowels are utilised in expansion joints to allow for the controlled movement of concrete sections due to temperature changes and prevent the formation of uncontrolled cracks.

- Construction Joints: When constructing large concrete structures, dowels are employed at construction joints to ensure load transfer between adjacent sections and prevent vertical displacement.

- Repair and Rehabilitation: In concrete repair and rehabilitation projects, dowels are utilised to restore the connection between existing and newly placed concrete, providing continuity and stability to the structure.

Dowels are commonly used to fix concrete cold joints and ensure structural integration and continuity – click here to read our article on concrete cold joints, if you want to understand how they are used to fix this issue.

What are the Types of Concrete Dowels?

Concrete dowels come in various types, each designed to meet specific technical requirements. Understanding the different types can help you choose what would be the most suitable option for your project.

- Plain Round Dowels: This type is the simplest and most commonly used. They provide direct load transfer and alignment between concrete sections.

- Epoxy-Coated Dowels: With a protective epoxy coating, they offer enhanced corrosion resistance for durability in moist and corrosive environments.

- Dowel Baskets: Pre-fabricated cages with interconnected dowels. They are Ideal for jointed concrete pavements, ensuring consistent spacing and alignment.

- Tapered Plate Dowels: Designed for concrete slabs, they facilitate load transfer while accommodating slab movement and reducing joint stresses.

- Dowel Sleeves: Used in expansion joints with temperature differentials, allowing controlled movement and reducing friction.

When to use each type of Concrete Dower?

Now that you know what dowels are, their applicability, and the existing different types, it is time to understand when kind each should be used to ensure optimal performance and functionality.

The table below summarises the types, common use and respective rationale.

Dowel Type | Applications | Reasons for Use |

Plain Round Dowels |

|

|

Epoxy-Coated Dowels |

|

|

Dowel Baskets |

|

|

Tapered Plate Dowels |

|

|

|

|

|

We note this table is indicative only, and each project and design will have its specific requirements.

FAQ

How far apart should dowels be in concrete pavement?

The spacing between dowels depends on various factors, such as the thickness of the concrete, the design loads, and thestructural design itself.

As a general guideline, structural engineers typically specify the spacing ranging from 12 to 18 times the thickness of the concrete slab.

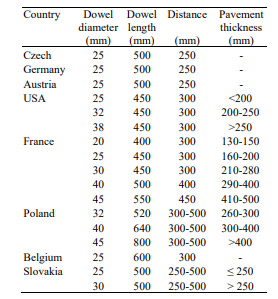

The table below was extracted from the article “Importance of dowels in transversal joints in concrete pavements” (by Jiri Grosek, Vladimir Chupik, Josef Stryk, and Ilja Brezina) and details a list of required dimensions (diameter and length) and spacing according to pavement thickness in different countries.

What is the difference between dowels and rebar?

While dowels are primarily used to enable load transfer and prevent differential movement/settlement between adjacent concrete sections, reinforcement bars (rebars) are used to reinforce the concrete and improve its resistance to tension loads.

Also, Rebars are typically placed within the concrete before pouring, while dowels are inserted into drilled holes in existing concrete.

Conclusion

In conclusion, concrete dowels play an important role in construction projects, and help with structural load transfer, alignment, and overall stability.

They are normally made of stainless steel and can come in different shapes and configuration, depending on the design specification and requirements.

We highly recommend you speaking to a structural engineer to understand the need for using them in your projects.