Construction agreements have evolved throughout the years, and there are many variations to suit the best risk allocation between owners and contractors. Among them, design and construct (D&C) contracts emerge as one the most used commercial frameworks.

But what exactly is a design and construction contract? Also known as design and build (D&B), this is a construction agreement in which the contractor is responsible (and assumes the risks) for both the design and construction phases of a project, with significant level of risk transfer from the Owner to the Contractor.

Overall, this approach tends to streamline integration between both cycles, decrease owner’s coordination needs, improve efficiency, and increase predictability of project costs and timelines.

In this article, we will explore D&C Contracts further, understand their pros and cons, compare them to the traditional construction-only approach, and briefly explore the existing variations – keep reading!

How does a Design and Construct (D&C) Contract Work?

In a D&C contract, the client/owner enters into a single contract with a construction company that provides both the design and construction.

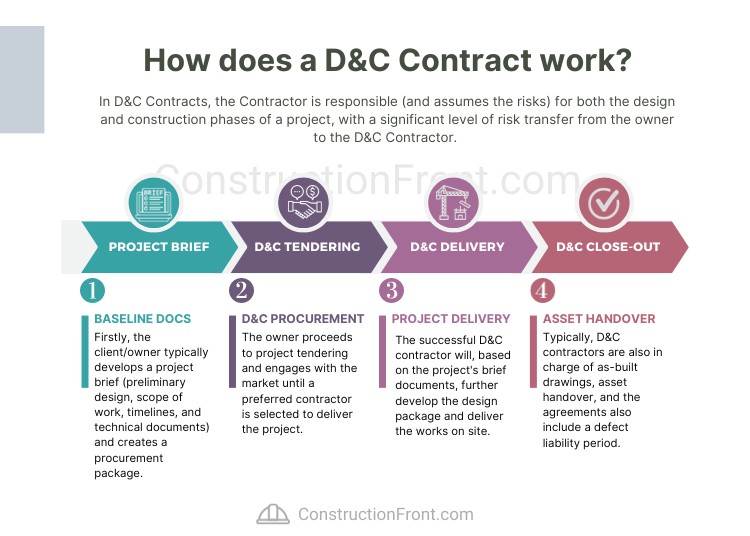

However, before doing so, the client/owner typically develops a project brief, including a preliminary design, a detailed scope of work, an indicative delivery program, and other documents, such as technical specifications, which combined form a procurement package (step 1 in picture below).

With the final package, the owner will proceed to project tendering and engage with the market until a preferred contractor is chosen to deliver the D&C Contract (step 2 in the picture below).

The successful D&C contractor will, based on the project’s brief documents, further develop the design package until it reaches the “approved for construction (AFC)” status and ultimately proceed to construction (step 3 in the picture below)

Typically, D&C contractors are also in charge of as-built drawings, asset handover, and the agreements also include a liability period of 12-24 months to deal with potential patent and/or latent defects (step 4 in the picture below)

Owner's Control over Design Development under a D&C Contract

It is important to note that the D&C model’s characteristics can vary depending on the extent of design undertaken by the client/owner and its preferences. Here are some common issues faced by an Owner that are worth noting:

- Owner prefers limited Control over Design: Overall, the level of control the Client has over the design decreases as design responsibilities shift to the Contractor. For instance, if the Client completes the concept design only, the Contractor is responsible for the entire design development and construction documentation, giving the Client minimal control over the detailed design.

- Owner prefers increased control over design: On the other hand, some clients may wish to retain increased control over design development and might develop (“in-house”) and provide a complete project scope and designs up to a particular stage (e.g., 100% schematic and 70% detailed design), giving the D&C Contractor less flexibility under the design packages.

Independent of the level of design control chosen by the Owner, it is essential that the contract clearly delineates the scope and responsibilities of each party.

D&C Contract vs Traditional Construction-Only Agreements - What are the main differences?

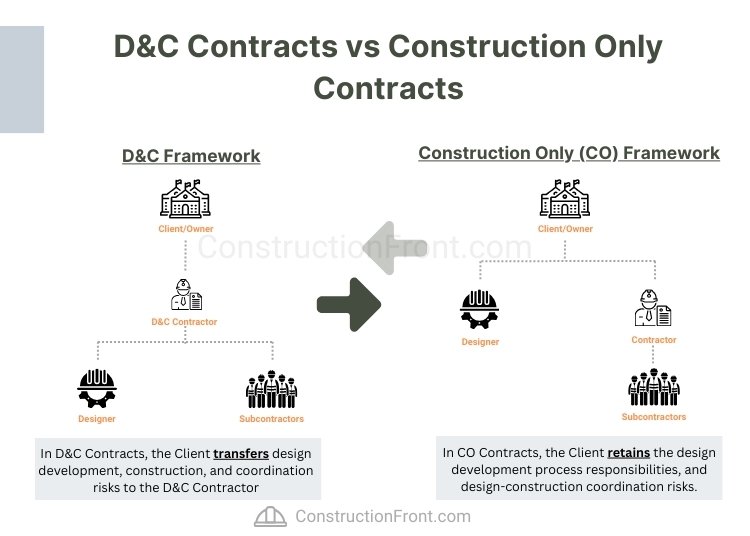

As indicated by the name, in Construction Only contracts, the Principal/Owner retains the design development process responsibilities and procures a contractor to deliver the construction works only.

This might be helpful for projects with decreased complexity, well-known construction methodologies, and where there is no significant added value in involving a contractor/builder in the design development process (i.e. construction of a house, refurbishment projects, etc.).

As the level of design complexity increases, owners might benefit from transferring the responsibilities and risks associated with design development to the contractor through a D&C agreement or even implementing an early contractor involvement framework.

Suggested Article: What is an Early Involvement Contractor (ECI) Agreement and How It Works?

The pictures and table below summarizes some of the key differences between D&C and Construction Only Contracts.

Author’s Note: Having worked in a Construction Only (CO) Contract for the Construction of the new Crows Nest Station in Sydney (Sydney Metro), I certainly do not recommend the CO approach for large scale and complex projects, given their dynamic nature and multiple design updates and changes required during project lifecycle.

Aspect | Design and Construct (D&C) Contract | Traditional Construction Only Contract |

Risk Allocation |

|

|

Project Coordination |

|

|

Cost and Time Predictability |

|

|

Client Control Over Design Development |

|

|

Mostly Used For / When |

|

|

D&C Contracts – Advantages and Disadvantages

Some of the pros and cons of D&C contracts are detailed below.

The Pros of D&C Contracting Framework

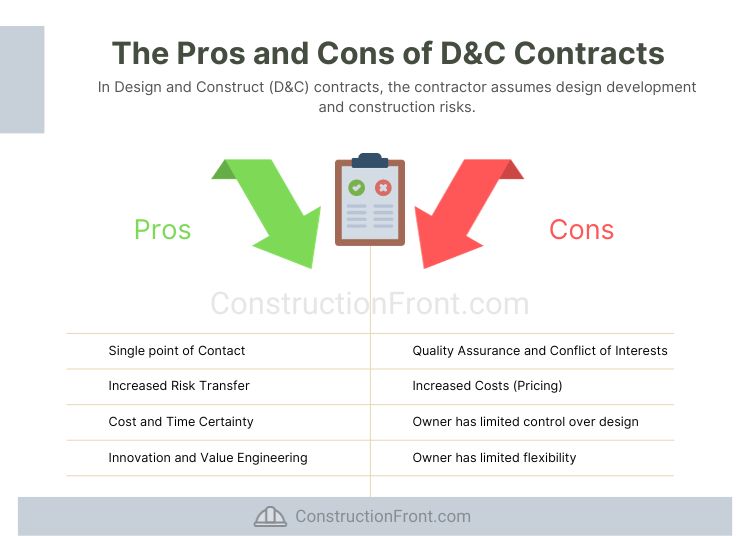

- Single-Point Accountability and Streamlined Project Management: D&C contracts provide clients with a single point of accountability and decrease the coordination burden for Owners. Also, integrating design and construction responsibilities within a single entity (the D&C Contractor) often leads to more efficient project management.

- Risk Transfer: This framework significantly shifts risks from the owner to the contractor, who is in charge of design development, project management, and full coordination of the construction phase.

- Increased Cost and Time Certainty: As a consequence of the level of risk transfer, clients have less exposure to cost blowouts and program delays.

- Innovation and Value Engineering: Given the level of control over design development, D&C Contractors have more flexibility to seek innovations and explore value engineering initiatives to reduce project costs and risks and deliver better outcomes for the owner.

The Cons and Risks of D&C Agreements

- Quality Assurance and Conflicts of Interest: Contractors may place a higher emphasis on cost savings and construction efficiency, which could affect the final product and project outcomes. Additionally, the responsibility for quality assurance shifts to the contractor, and clients must still oversee both the design and construction phases to ensure adherence to contracted standards.

- Increased offer pricing: Given the level of risk and scope transfer, contractors typically increase their contingency allowance in their tender and, ultimately, offered price.

- Owner’s control over the design is limited: As previously detailed, owners opting for D&C contracts typically have less control over the design phase.

- Limited flexibility: Once the contract is executed, owners typically have limited flexibility to change and update technical specifications and documents, concept design, preliminary drawings, etc.

Even though design development responsibilities are typically fully transferred to the D&C Contractor, owners can still request changes through contract mechanisms, such as variation orders. However, these changes are usually associated with a cost increase and, depending on the nature of the design alteration, might trigger the submission of an extension of time claim by the Contractor and disputes between the parties.

When should a design and construct contract be used?

The D&C Contracting framework is usually implemented in/when:

- The risks associated with changes in design and construction processes are minimal.

- The client/owner has solid experience in developing concept/schematic design.

- Projects in which the constructability element is pivotal in the design development process, and contractors’ inputs are not only valuable but also mandatory for project success.

- The contractor is best placed to take on board design risks.

- Greenfield or brownfield projects where the risk can be assessed and priced.

D&C Contract - Examples

Recent Projects awarded under the D&C Contracting Framework:

How to procure and manage a D&C Contract?

Key Elements for D&C Contract Procurement

While preparing for the procurement of D&C packages, owners should consider the following key feature as a minimum for potential tenderers:

- Successful track record in delivering project under D&C agreements.

- Strong engineering and design skills to further develop the initial concept design.

- Robust project management and coordination skills to ensure seamless integration between the construction and design elements.

- Solid experience in delivering similar projects and ability to incorporate lessons learnt from previous project and optimize design and constructability aspects.

- Financial Capacity, especially when the Design-Build-Finance approach is used (further details below).

Key Elements to Manage a D&C Contract

During the delivery phase, it is essential that the owner’s team:

- Can proactively manage and mitigate variations.

- Oversee design development to ensure adherence to contracted standards.

- Have a strong understanding of D&C agreements.

- Robust contract management skills and ability to manage contracted scope

D&C Contracts - Variations

D&C Agreements have a wide variety of variations, which include (but are not limited to):

- DCF – Design, Construct, and Finance – D&C Contractor also takes on board the project financing responsibility, significantly increasing financial and commercial risks to the Contractor (akin to a PPP contract).

- DCM – Design, Construct, and Maintain – In this framework, Contractors are also responsible for the maintenance of the asset after construction completion.

- DNC – Design, Novate, and Construct – In this approach, the D&C contractor novates the design agreement between the owner and its design consultant and works with the consultant to finalise the design development.

What are the altenartives to D&C Contracts?

Some of the alternatives to the D&C Contracts are detailed below. For further details on each model, we suggest reading the following articles:

Contracting Approach | Description | Advantages | Disadvantages |

Construction Management (CM) | A construction manager is hired early in the project to provide project management advice, including constructability and design development. | – Early input on constructability and cost. – Potential for faster project delivery. – Strong project management. | – Additional management fees. – Potential conflicts between construction manager and design professionals. |

Engineering, Procurement, and Construction (EPC) | A single entity handles design, procurement of materials, and construction, commonly used in energy and infrastructure sectors. | – Turnkey solution with a single point of accountability. – Streamlined project management – Reduced client involvement and risk. | – Higher upfront costs. – Limited client design control. – Risk of conflicts of interest. |

Alliance Contract | A collaborative approach where all project stakeholders, including the owner, designer, and contractor, form an alliance to share risks, rewards, and decision-making throughout the project. | – High level of collaboration and integration. – Shared risk and reward structure. – Potential for innovation and value engineering. | – Complex management and legal arrangements. – Requires strong team alignment and communication. – May not be suitable for all project types. |

Managing Contractor | A managing contractor is engaged by the owner to oversee the project, manage subcontractors, and provide input during the design and construction phases. | – Expert project management. – Early input on constructability and cost. – Client maintains design control. | – Potential for higher management fees. – Requires clear delineation of responsibilities to avoid conflicts. |

Need Help?

Do not hesitate to contact us (click here) for specialised advice in construction contracts.